The KSMC-iX is a high-accuracy motion controller engineered for applications demanding sub-micron positioning precision and deterministic high-speed axis control. Built on a proprietary 10 Gbps fiber communication architecture, this precision motion control system delivers ultra-fast control loops with position update rates up to 50 kHz and current loop processing at 100 kHz, enabling the extreme accuracy required for EDM systems, precision CNC machining, and advanced semiconductor manufacturing equipment.

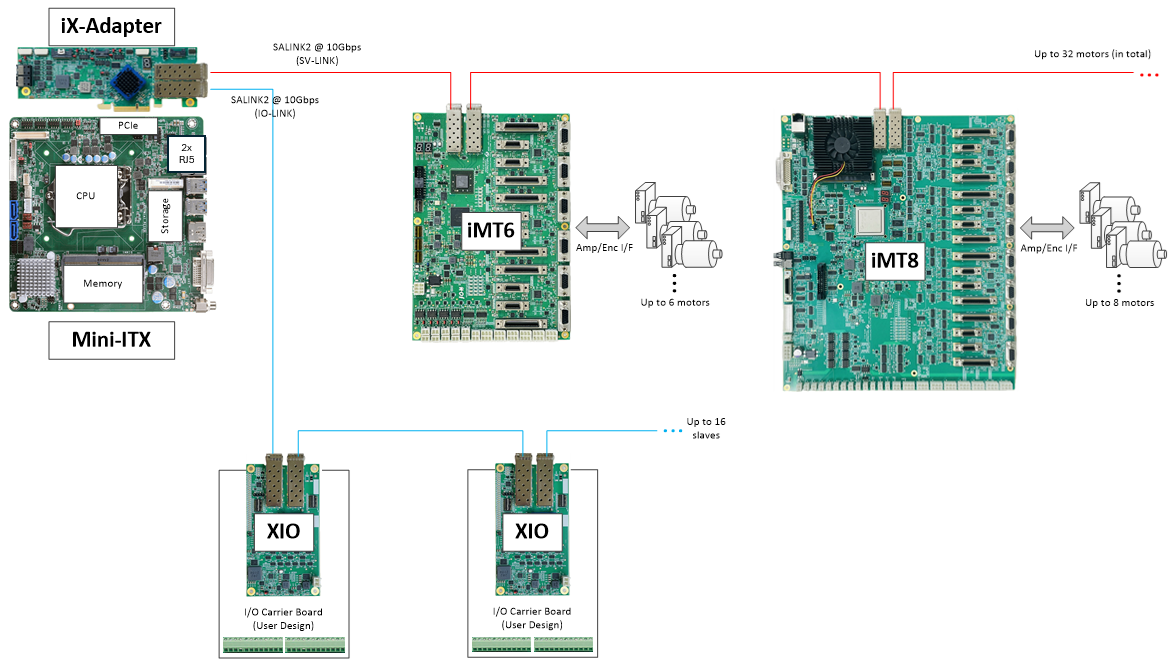

KSMC-iX System Architecture

Hardware Specificaton

High-Performance Controller Hardware Architecture

- Multi-board solution with 10 Gbps fiber optical communication for deterministic high-speed data transfer

- 2× SFP+ modules for 10 Gbps communication (SALINK2 – proprietary protocol)

- Host

- Mini-ITX with PCIe extension slot (PCIe 4x Gen2)

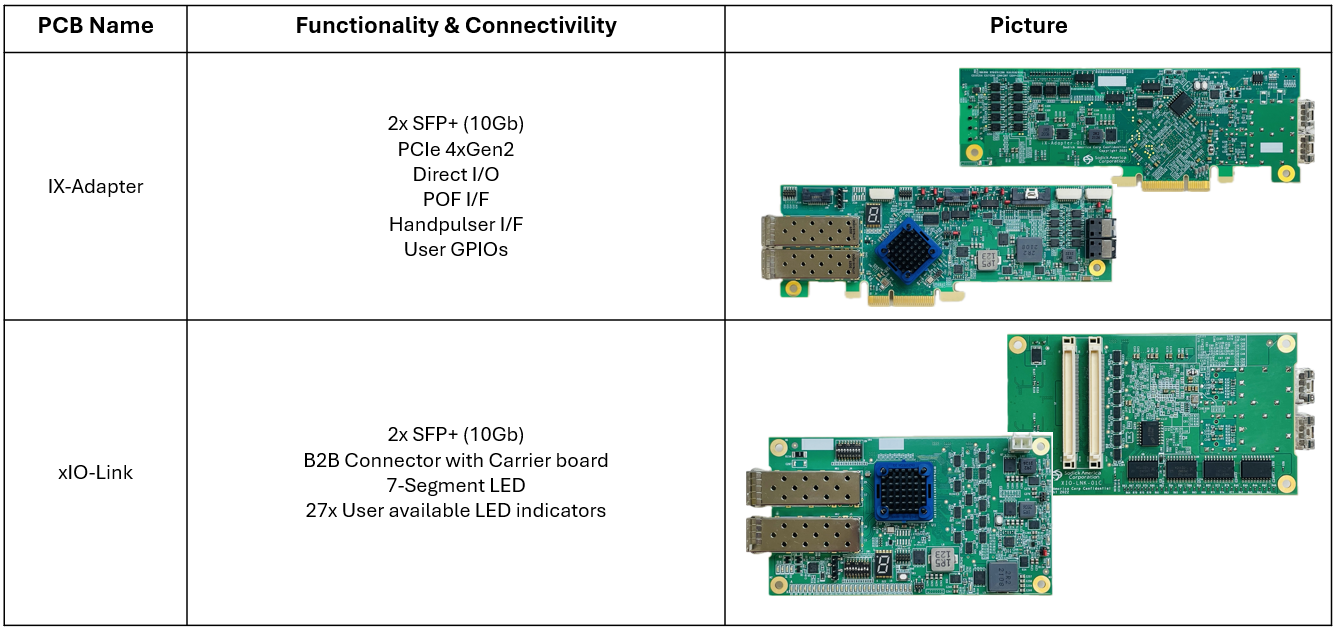

- iX-Adapter (PCIe extension board) as a communication interface

- Slave Modules

- xIO-Link – General-purpose communication board with B2B connector (for GPIO expansion)

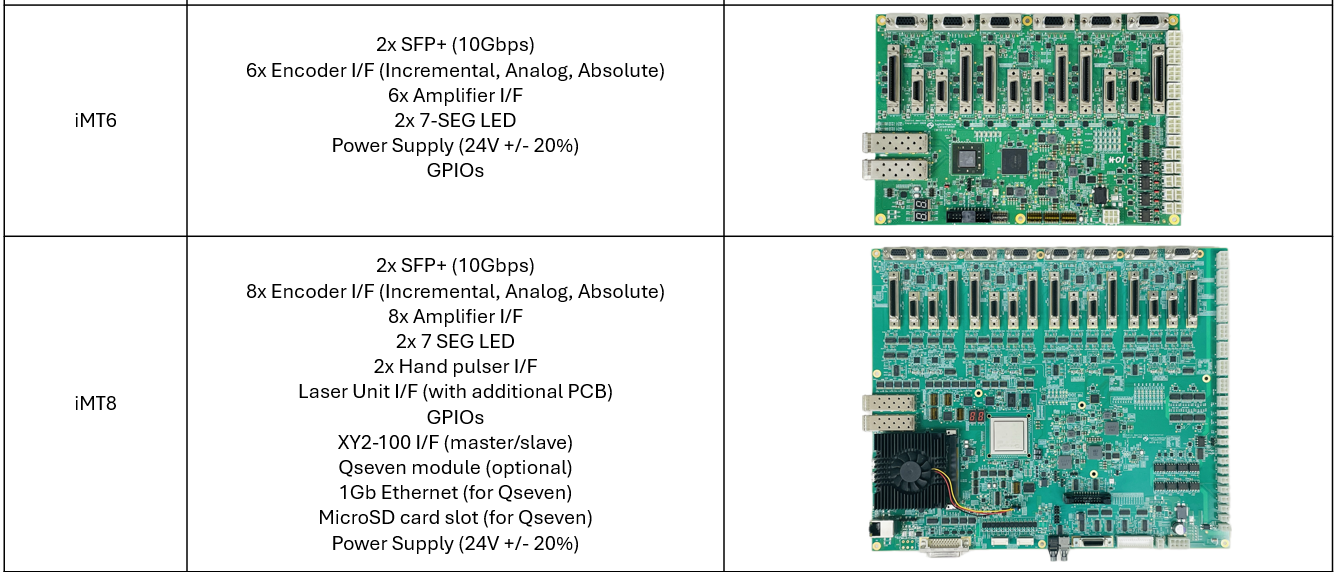

- iMT6 – Motor interface board for standard servo applications

- iMT8 – High-performance motor interface board with ARM processor on Q7 (QSeven) module

Software Specification

- RTOS (Real Time Operating System) – INtime (by TenAsys)

- Motion Controller with advanced control features (refer to specifications table)

- GPOS (General Purpose Operating System) – Windows 10/11

- User Interface (Optional)

- User Application

- OPC-UA server, MTConnect Adapter

| Feature | Description |

|---|---|

| Program | NC program with G, M, T code for EDM (Sinker and Wire), Machining Centers |

| Motion Program for high-speed axis control in Motion Coordinate System | |

| Periodic PLC for I/O control and process synchronization | |

| Controllable Motors | 32 |

| Interpolatable Axes | 8 |

| Motion Coordinate System | 4 |

| Motion Segmentation Time | >= 200 usec |

| Amplifier Interfaces Supported | PWM, Analog Linear, Pulse Train |

| Motor | AC Servo (Rotary/Linear), Stepper, DC |

| Encoder interfaces supported | Incremental, Analog, Absolute (EnDat, Tamagawa) |

| Move Mode | Jog, Homing, Trigger, Spline, Linear, Rapid, CW, CCW, PVT |

| Controller | Position/Velocity control: Conventional PID, Modern Control Theory (Disturbance Observer, Sliding Mode Controller, Adaptive Control) |

| Current Control: PI control in FPGA | |

| Controller Update Cycle/ Freq | Postion/Velocity Loop: >= 20 usec (50 KHz) |

| Current Loop: >= 10 usec (100 KHz) |

Board Interface Details

Comparison with EtherCAT-Based Motion Controllers

The KSMC-iX uses a proprietary 10 Gbps fiber protocol for applications requiring maximum performance and deterministic control beyond EtherCAT capabilities. For systems where EtherCAT network integration, distributed I/O architecture, or PLC convergence are priorities, our EM3 and EM4 controllers provide deterministic real-time control with industry-standard network compatibility.