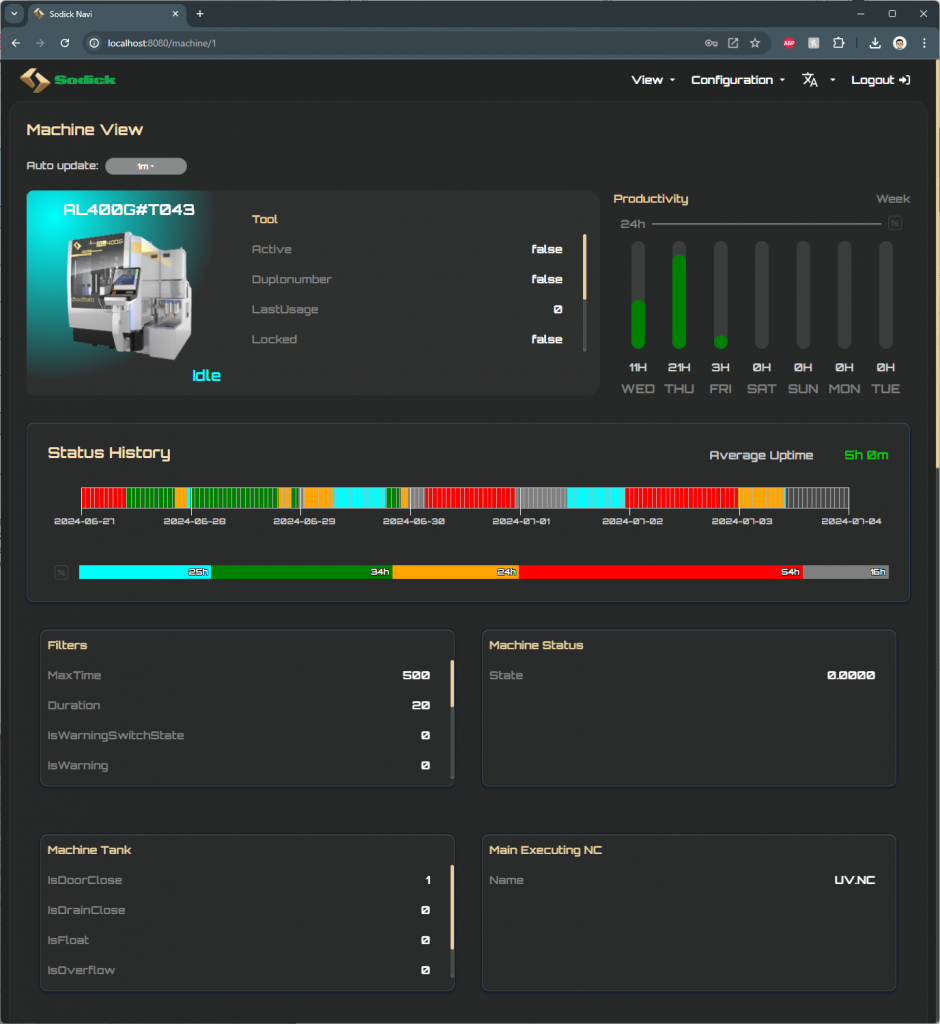

Sodick America Navi Web Server is an On-Premises website which shows real-time data and operating status of any OPC or MTConnect equipped machines.

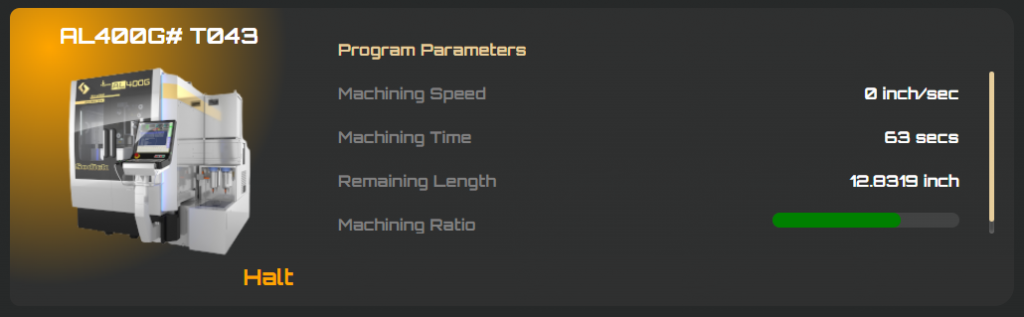

For each machine you may display any data items that are available for data collection. Data items may be grouped together in “Categories”, which are fully configurable.

Statistics on Up-Time are calculated and shown via bar graphs on the “Machine” page, giving you insight on productivity.

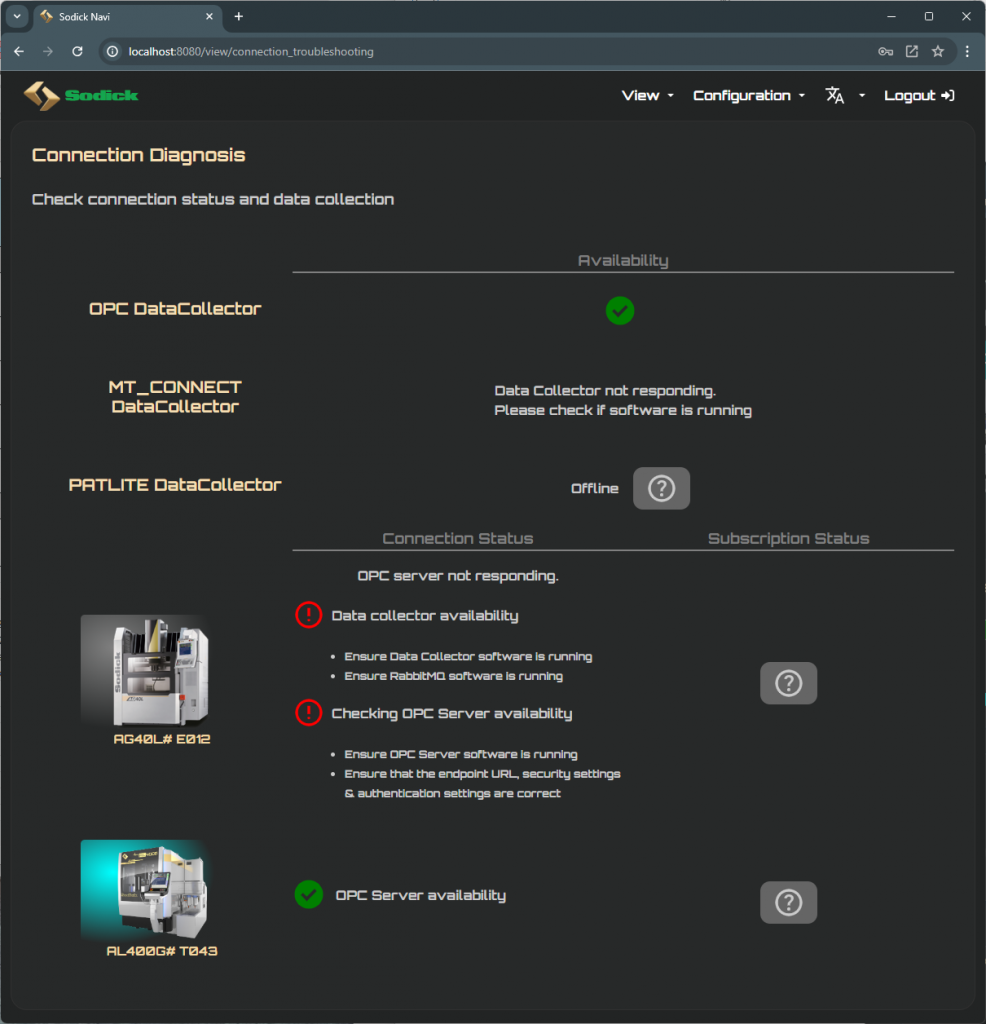

Navi Web Server works together with Sodick America Data Collectors to provide real-time information of your machining tools on the same network. Sodick America provides data collectors for OPC UA, MTConnect, and Patlite (AirGrid) communication protocols. Connection diagnosis and troubleshooting tools available, providing solutions for disconnected machines. The software may be installed on any PC running the Windows Operating System.

Key Features

- Real-Time Monitoring

- Continuously track the performance and health of your industrial equipment and processes, ensuring optimal operation and early detection of potential issues.

- Predictive Maintenance

- Utilize data analytics to predict equipment failures before they happen, reducing downtime and maintenance costs.

- Cloud Connectivity

- Securely connect your devices and systems to the On-Premise server, enabling remote access and control, as well as data storage and analysis.

- Scalable Architecture

- Easily scale your IIoT implementation from a single device to a full-scale industrial network, adapting to your growing needs.

- Customizability

- Create your own categories and assign units to any data item being collected.

- Data Analytics and Visualization

- Gain insights from your data with powerful analytics tools and intuitive dashboards, helping you make informed decisions.

Applications

- CNC Machines

- Robotics

- Semiconductor Manufacturing

- Smart Manufacturing

- Environmental Monitoring

- Asset Tracking

Benefits

- Increased Efficiency

- Streamline operations and improve resource utilization with real-time data and analytics.

- Enhanced Reliability

- Predict and prevent equipment failures, reducing downtime and maintenance costs.

- Better Decision Making

- Leverage data-driven insights to optimize processes and improve overall performance.

- Cost Savings

- Reduce operational costs through improved efficiency, predictive maintenance, and optimized resource use.

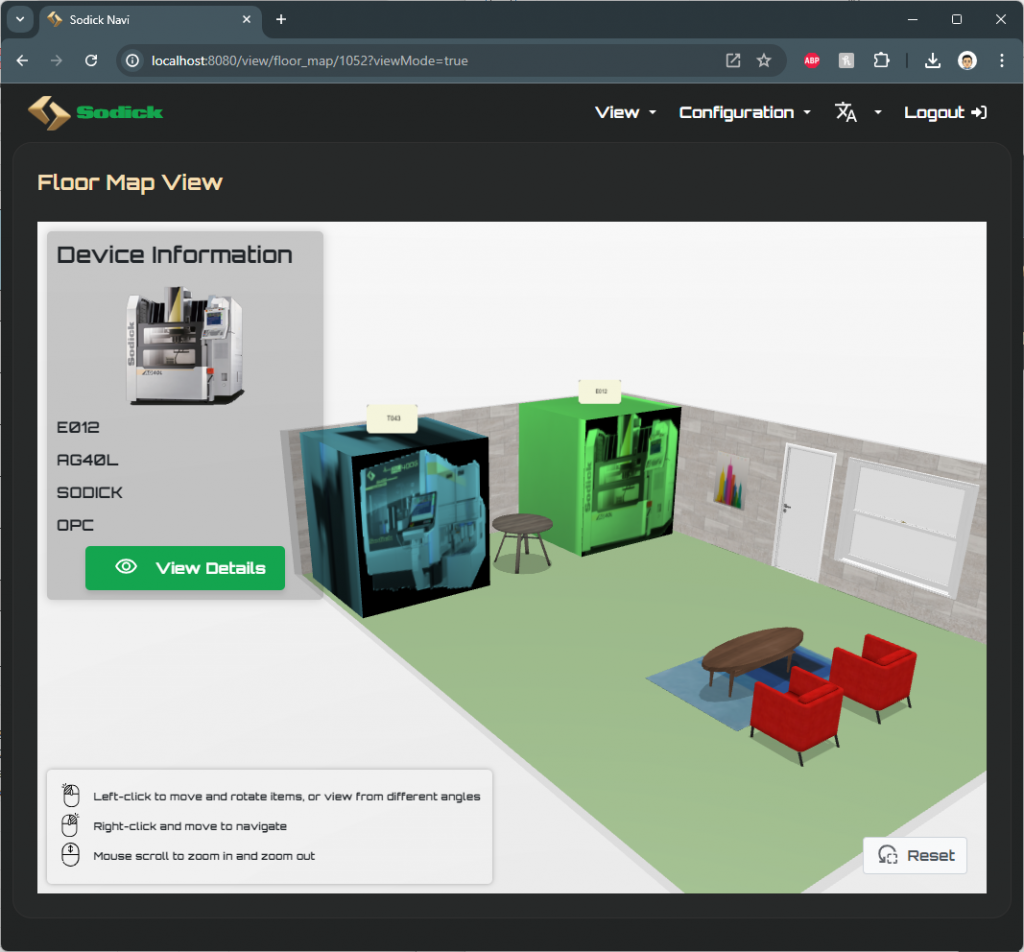

Floor Mapping

Create your own 3D floor map by adding registered machines, doors, windows, and more. Real-time statuses are reflected on the floor map, showing if the machine is idle, running, halted, or in error.