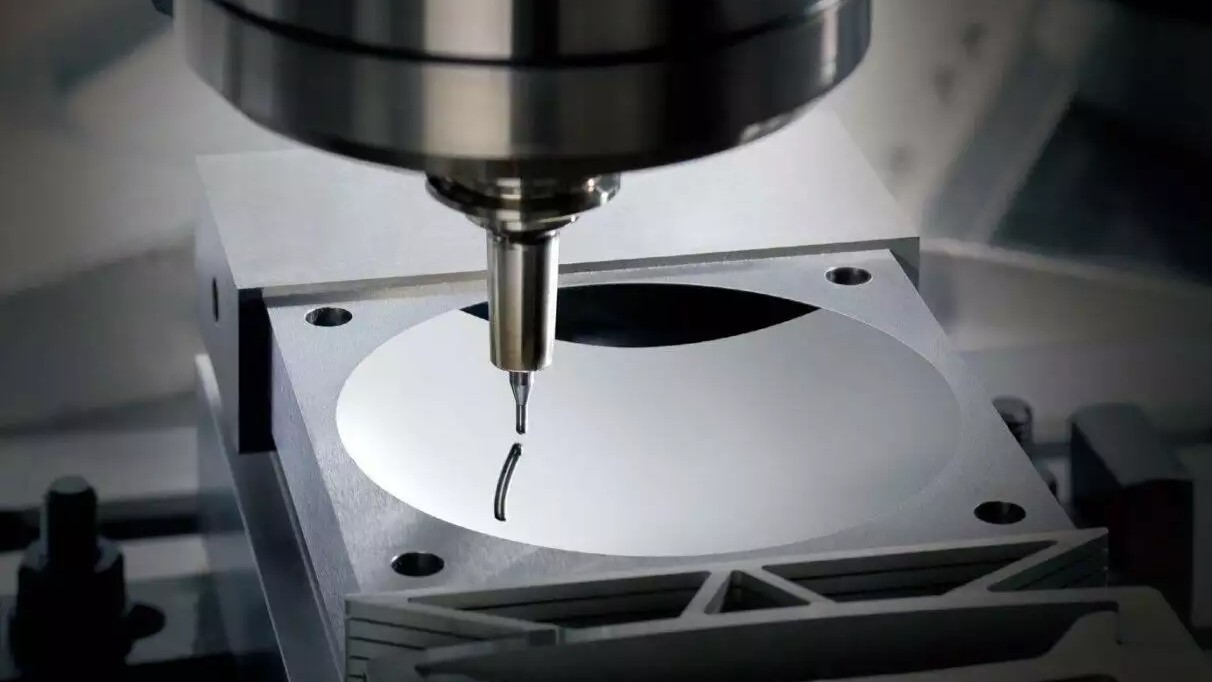

Achieve Unmatched Accuracy & Throughput with an Advanced CNC Motion Control System

When precision CNC machining meets high-performance motion control, your manufacturing operations reach new levels of accuracy and throughput. Sodick America’s advanced CNC systems deliver the deterministic motion control and multi-axis synchronization needed for high-volume CNC machining environments where sub-micron accuracy and real-time CNC control are non-negotiable.

At the heart of this transformation are two cutting-edge control solutions that power everything from high-speed CNC machining centers to complex EDM operations.

Solution 1: Ultra-High Performance CNC Motion Control System for Advanced Manufacturing

Max-out your motion control with the KSMC-iX Motion Controller, a CNC motion control system designed for ultra-high-speed, ultra-accurate movement. With support for up to 32 motors, sub-200 µs segmentation, and 10 Gbps fiber links, it delivers the ultra-low latency motion systems required for next-generation precision CNC machining that demands extreme repeatability and speed.

The KSMC-iX excels in high-speed CNC machining applications where servo control and feedback loops must respond in microseconds, enabling the tight tolerances and surface finishes that aerospace, medical device, and semiconductor manufacturers require.

Solution 2: EtherCAT CNC Controller for Smart Factory Automation

Scale your automation with KSMC-EtherCAT Products, offering high-speed, deterministic EtherCAT network control for motion, I/O, PLC integration, and Industrial IoT (IIoT) readiness. This EtherCAT CNC controller solution is ideal for smart factory automation and high-volume CNC machining setups where multiple axes, servos, sensors, and networked devices need synchronized control without compromise.

EtherCAT’s high-speed data communication enables real-time CNC control across your entire production line, seamlessly integrating CNC systems with manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms for complete production visibility and control.

Whether you’re building a high-precision micro-machining center or a fully networked multi-axis CNC production line, these advanced CNC motion control systems give you the responsiveness, multi-axis synchronization, and deterministic performance required for modern precision CNC machining operations.