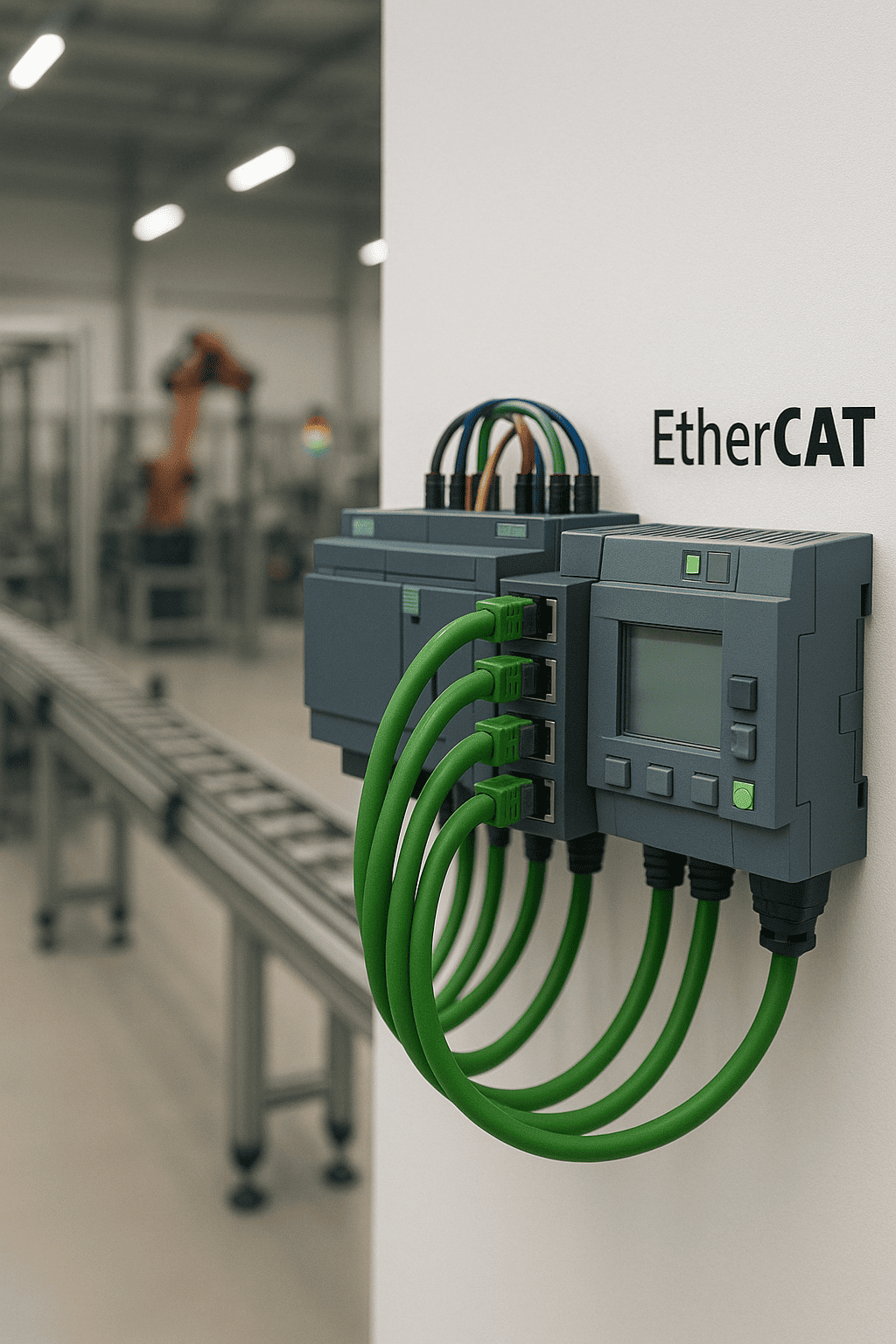

Our EtherCAT Master Board solutions deliver deterministic, real-time communication systems for industrial automation hardware. EtherCAT technology enables ultra-fast data exchange with microsecond-level precision, essential for synchronized motion control, distributed I/O networks, and converged motion-PLC architectures.

EtherCAT Master 3 (EM3)

External Hardware-Based EtherCAT Master Board

Transform any PC into an industrial motion controller with the EM3, an FPGA-based EtherCAT Master Board that delivers deterministic real-time communication without modifying your existing computer. The FPGA architecture ensures consistent cycle times independent of PC operating system overhead.

✔ FPGA-timed EtherCAT real-time control independent of PC load

✔ Fast deployment, operational in minutes

✔ Integrated IEC 61131-3 PLC with OPC-UA interface

✔ Hardware-based deterministic communication

EtherCAT Master 4 (EM4)

Industrial PC-Based Real-Time Communication System

A complete industrial automation hardware platform engineered for real-time EtherCAT control, multi-axis motion, and PLC functionality in a single rugged industrial PC. The EM4 eliminates integration complexity with a pre-configured, tested system ready for immediate deployment in harsh industrial environments.

✔ Complete industrial PC with integrated EtherCAT Master functionality

✔ Real-time communication system optimized for industrial automation

✔ Unified motion control and PLC on a single platform

✔ Rugged enclosure for harsh factory environments

Unified Motion, PLC, and EtherCAT Control Platform

Sodick America’s EtherCAT ecosystem integrates motion control, PLC logic, and real-time networking into a single software architecture. This convergence eliminates the complexity and latency of traditional distributed control systems, where separate controllers create integration challenges and performance bottlenecks.

EtherCAT -Master

Command.

Central EtherCAT configuration tool managing real-time communication across all connected devices. Configure network topology, assign addresses, and verify network integrity.

SA Motion

Move.

Advanced motion control algorithms optimized for EtherCAT-based servo systems. Supports coordinated multi-axis trajectories, electronic gearing, and complex path interpolation.

PLC

Control.

IEC 61131-3 compliant PLC environment running on the same EtherCAT real-time platform as motion control, eliminating communication delays between motion and logic.

RDI-L

Debug.

Captures and visualizes real-time motion behavior, servo feedback, and network performance metrics, accelerating commissioning and troubleshooting.

Key Features – Why EtherCAT Real-Time Technology Matters

- High-Performance, Deterministic Communicationnce

- EtherCAT’s hardware-based frame processing delivers consistent cycle times regardless of network load. This enables synchronized motion across multiple axes with microsecond timing accuracy, which is essential for CNC machining, packaging equipment, and robotic assembly.

- Scalable Architecture

- Scale from single-machine configurations to factory-wide systems without performance degradation. The same EtherCAT Master Board controls standalone machines or coordinates hundreds of distributed I/O points and servo axes.

- Flexible Integration

- Supports multiple protocols beyond EtherCAT, including OPC-UA, Modbus TCP, and PROFINET gateways. Allows gradual migration from legacy systems without complete equipment replacement.

- Comprehensive Software

- Complete software stack including EtherCAT configuration tool, motion libraries, PLC development environment, and diagnostic tools. Pre-built function blocks accelerate development from concept to commissioning.

Applications – Industries Deploying EtherCAT Real-Time Automation

- Factory Automation

- Process Control

- Machine Building

- Automotive Industry

- Renewable Energy Systems

Benefits – What EtherCAT Master Board Technology Can Do For You

- Enhanced Efficiency

- Streamline your automation processes with reliable and high-speed communication.

- Reduced Downtime

- Minimize disruptions with robust and fault-tolerant networking solutions.

- Future-Proof

- Stay ahead with scalable and flexible technology that adapts to evolving industrial requirements.