Our EtherCAT Master and Slave Boards provide high-speed, real-time communication for industrial automation systems. EtherCAT technology ensures fast and deterministic data exchange, crucial for modern automated processes.

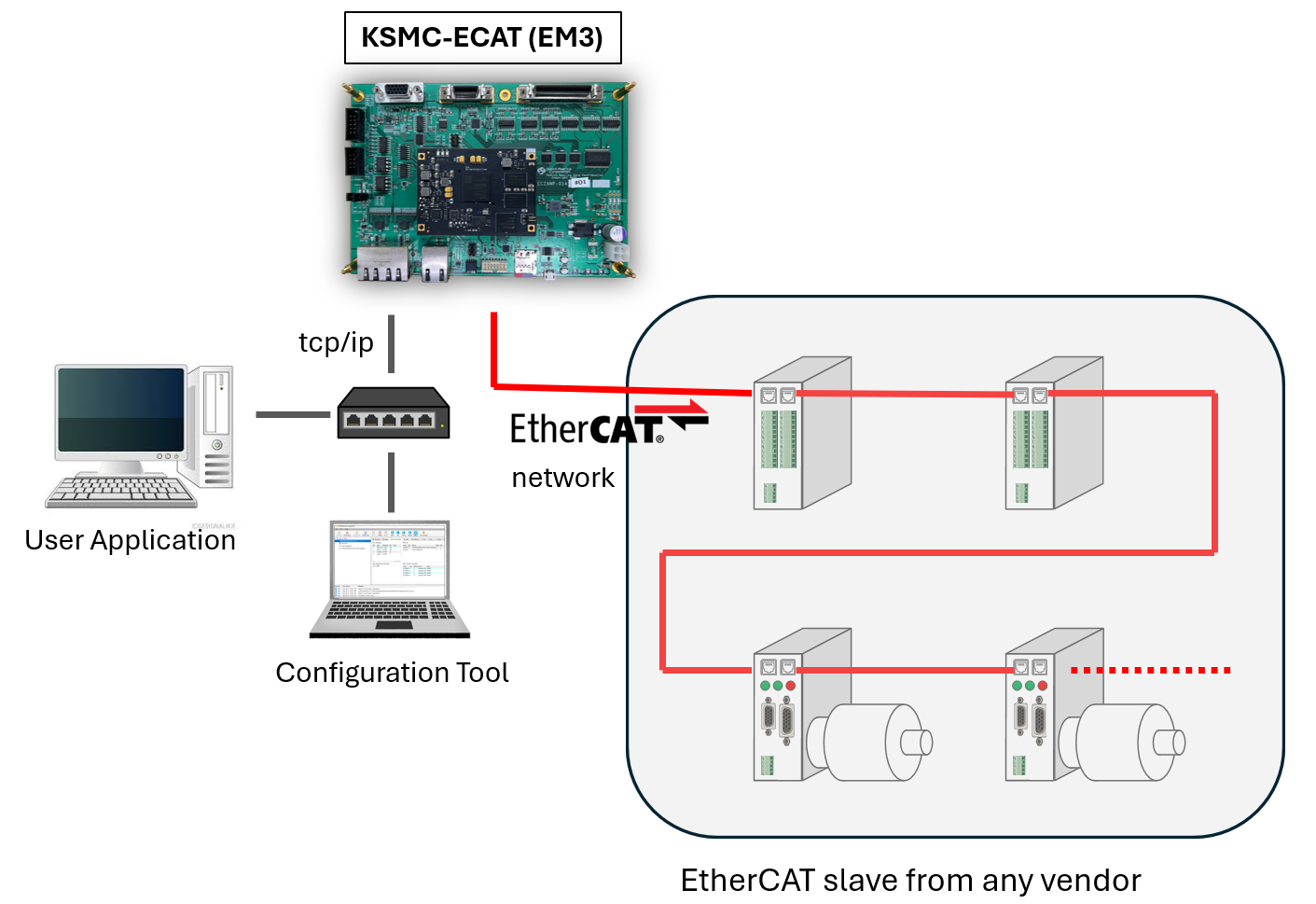

KSMC-EtherCAT Master (EM3)

(External Hardware based solution)

System:

- ZYNQ System on Chip as the main processing module

- FreeRTOS Real-time operating system

EtherCAT Master Features:

- Distributed Clock

- Cable Redundancy

- Deterministic and very fast Process Data Object (PDO) cycle

- Graphical Configuration Tool

Motion Controller:

- Up to 32 motors

- Up to 16 interpolated axes

- Motor-Axis association (Axis Define)

- Motion Program

- Periodic PLC

- Various Motion Movement Types

- Data Gathering (easier for debugging)

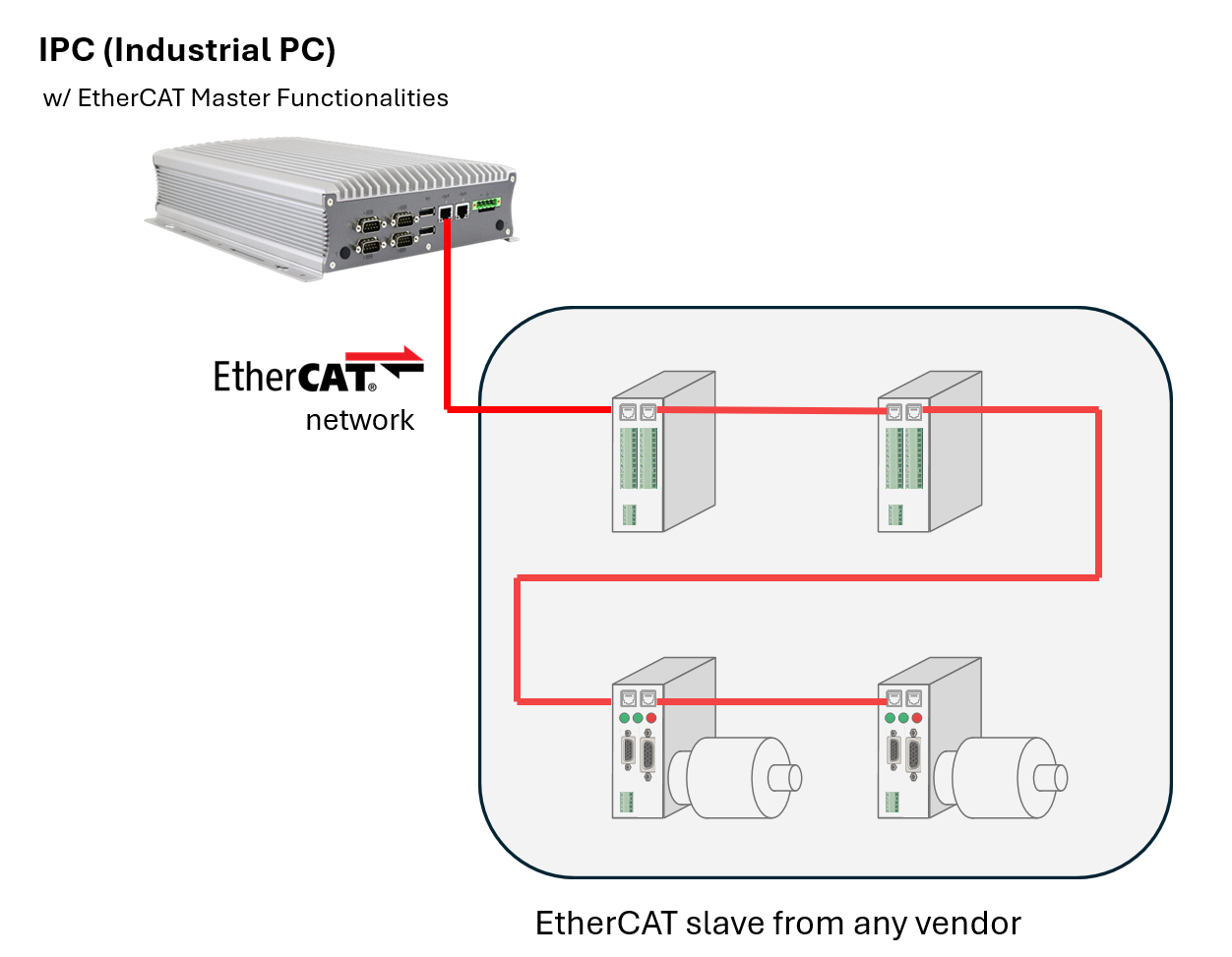

KSMC-EtherCAT Master (EM4)

System:

- i5-12500TE as the main processing module

- Windows General purpose operating system

- TenAsys INtime or Xenomai Cobalt Real-time operating system

EtherCAT Master Features:

- Distributed Clock

- Cable Redundancy

- Deterministic and fast Process Data Object (PDO) cycle

- Supports CiA402 Drive profile

- Graphical Configuration Tool

Motion Controller:

- Up to 32 motors

- Up to 16 interpolated axes

- Motor-Axis association (Axis Define)

- Motion Program

- Periodic PLC

- Various Motion Movement Types

- Data Gathering (easier for debugging)

Key Features

- High Performance

- Capable of handling high-speed data transfer with low latency, ensuring timely and accurate communication.

- Scalable Architecture

- Supports a wide range of network sizes, from small systems to large-scale industrial networks.

- Flexible Integration

- Compatible with various industrial protocols and can be easily integrated into existing automation systems.

- Reliable Communication

- Ensures robust and error-free data exchange, even in demanding environments.

- Comprehensive Software Support

- Comes with extensive software tools for easy configuration, diagnostics, and maintenance.

Applications

- Factory Automation

- Process Control

- Machine Building

- Automotive Industry

- Renewable Energy Systems

Benefits

- Enhanced Efficiency

- Streamline your automation processes with reliable and high-speed communication.

- Reduced Downtime

- Minimize disruptions with robust and fault-tolerant networking solutions.

- Future-Proof

- Stay ahead with scalable and flexible technology that adapts to evolving industrial requirements.